Book Appointment Now

About us

WHY CHOOSE

Zhongyuan Qichuang?

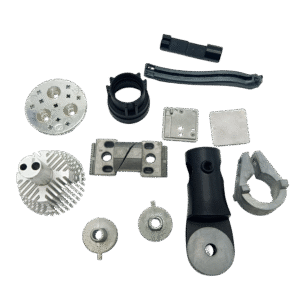

Dongguan Zhongyuan Qichuang Technology Co., Ltd and Dongguan City Jia zhan Die Cast Co., Ltd are affiliated companies which locate in Dongguan City (in Chang’an and Qiaotou seperately). We are the comprehensive enterprises that produces hardware accessories professionally. Our business principle is “quality first and integrity first” and our service tenet is“all for customers”. Our main business: zinc/aluminum alloy die-casting. We own machines: two 800T, two 630T, one 420T, and two 280T. Zinc alloy die-casting machines: six sets, CNC machines: twenty sets.

By our professional techniques and experiences calculated for many years, we service many major customers in electron, decorative lighting, furniture and auto mobile accessory with our high-quality products and superb modes of business operation. We have a group of outstanding technical elites who are acknowledged, loved and supported by massive customers by our employees’ extra efforts.

DIE CASTING PROCESS

We offer die casting tonnages from 88T to 1250T and precision parts processing capabilities up to approximately 1 meter in size, meeting the diverse needs of different industries.

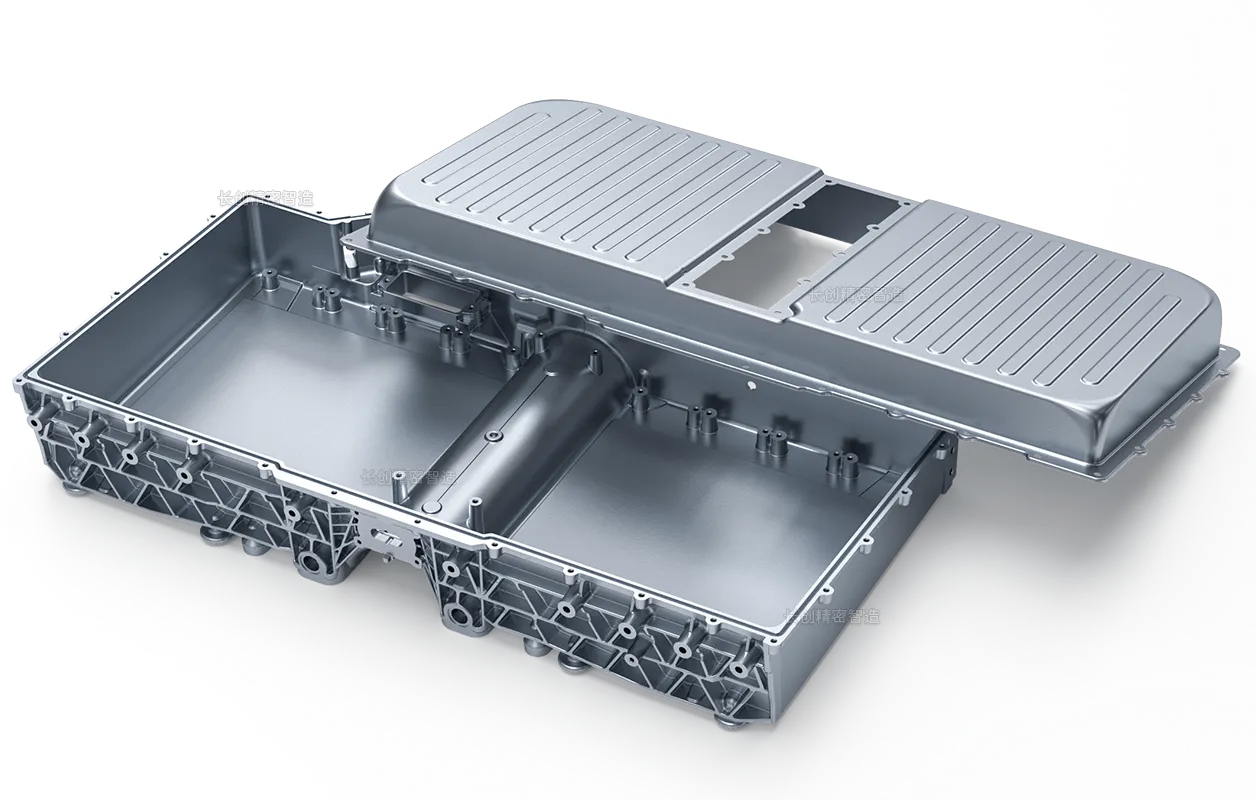

Aluminum Alloy Die Casting

Aluminum alloy die-cast parts have excellent thermal and electrical conductivity, making them widely used in automotive and electronics industries. Our advanced casting techniques ensure precise dimensions and superior surface quality for every component.

Learn MoreZinc Alloy Die Casting

Zinc alloy die-cast parts have excellent machinability and stable mechanical properties, suitable for precision part manufacturing. They offer superior finishing capabilities and are ideal for decorative and functional components.

Learn MoreMagnesium Alloy Die Casting

Magnesium alloy die-cast parts, with their lightweight and high-strength characteristics, are ideal for aerospace and 3C products. They provide excellent strength-to-weight ratio and are perfect for applications where weight reduction is critical.

Learn MoreThe Importance of Die Casting Molds

A properly designed aluminum alloy die casting mold is essential for successful project development and ensures high-quality die castings. The mold directly impacts production efficiency, part quality, and overall manufacturing costs.

Determine Shape and Dimensional Accuracy

The dimensional accuracy of the mold cavity directly determines the accuracy of the die casting, ensuring it meets design requirements and fits perfectly with other components.

Affect Die Casting Quality

The mold's gating system optimizes aluminum alloy filling, while a good exhaust system reduces defects like porosity and ensures uniform part density.

Improve Production Efficiency

A reasonable mold structure speeds up operations like mold opening/closing, reducing unnecessary auxiliary time and greatly improving production efficiency.

ISO Certified Quality

Our mold manufacturing strictly adheres to ISO standards, ensuring stable and reliable production performance.

ISO Certified Quality

Our mold manufacturing strictly adheres to ISO standards, ensuring stable and reliable production performance.

Alloy Materials Comparison

Choose the right alloy based on properties and scenarios.

| Property | Al Alloy | Zn Alloy | Mg Alloy |

|---|---|---|---|

| Density (g/cm³) | ~2.7 | ~6.6 | 1.7-1.9 |

| Cost | Moderate | Lower | Higher |

| Strength | High | Medium | Relatively High |

| Thermal Conductivity | Excellent | Medium | Good |

| Corrosion Resistance | Good | Excellent | Medium |

| Processing Difficulty | Medium | Low | High |

| Applications | Auto parts, heat dissipation components | Electronic enclosures, hardware | Aerospace, 3C casings |

Precision Metal Stamping & Mold Engineering

Specializing in metal stamping components and comprehensive mold development, we excel in end-to-end solutions from design to manufacturing. Equipped with advanced stamping presses, deep drawing systems, and precision mold fabrication facilities, our capabilities span complex geometries for automotive, electronics, and consumer industries.

Our ethos revolves around:

- Technical Eminence:CAD/CAM-optimized mold design and progressive die solutions that redefine manufacturing precision.

- Quality Paragon:ISO-certified protocols ensuring every stamping meets rigorous standards, from material analysis to dimensional verification.

- Collaborative Expertise:A dedicated team of engineers partners with clients to refine designs for optimal manufacturability, merging innovation with efficiency.

Our core product

Engineered for Precision, Crafted for Impact

Specialized In Precision Zn Al Alloy Die Casting

Electronic appliances

Engineered with our top – notch Zn – Al alloy die casting, these components are the perfect fit for 3C products. They ensure stable performance, with outstanding heat dissipation properties. The precision – crafted connectors and housings for smartphones and laptops achieve an ultra – fine tolerance of ±0.01mm, safeguarding reliable electrical connections and protecting internal circuits from external interference.

Automotive Structural Parts

Crafted for durability and lightweight design, our automotive Zn – Al alloy die – cast parts play a crucial role in vehicle manufacturing. Parts like engine brackets and transmission housings are designed to withstand high mechanical stress. With a 15% weight reduction compared to traditional materials, they contribute to enhanced fuel efficiency while maintaining the vehicle’s structural integrity, all while meeting strict automotive industry quality standards.

Connector Housing Die - Casting Service Provider

Aluminum Alloy and Zinc Alloy Die-Casting Customization and Sales Services.

Aluminum Alloy and Zinc Alloy Die-Casting Customization and Sales Services Our expertise lies in the design, customization, and sale of precision die-casting solutions for aluminum

Aluminum / Zinc Alloy Die-Casting Molds and Finished Products –Integrated Customized Foreign Trade Service.

Our company specializes in customized aluminum and zinc alloy die-casting services tailored for international trade. We offer a one-stop solution that includes high-quality die-casting alongside

Understand the production process of custom aluminum and zinc die casting reveals its intricate and highly skilled nature.

This manufacturing method involves pouring molten aluminum or zinc at high pressure and speed into enduring molds crafted from hot working steel. The result is

Competitive Prices for All Metal Resistance Element Solutions

We offer a diverse range of metal resistance element products, engineered to meet strict industry standards.

Copper - Based Resistance Elements

High – conductivity copper – alloy resistance elements, ideal for applications requiring stable current regulation. Suitable for industrial heating, power supply systems, etc.

Precision Stainless Steel Elements

Stainless steel resistance elements with ultra – precise resistance values. Perfect for high – tech electronics, sensor modules, ensuring long – term reliability.

Custom Alloy Resistance Elements

Tailored alloy resistance elements, designed to your unique technical specs. For specialized industries like aerospace, new energy, meeting extreme environment demands.

Metal Resistance Element Precision Design Reliable Performance

Our team of professional engineers, with rich experience in metal resistance technology, focuses on providing customized solutions. From standard resistance element production to high – precision, special – requirement R & D and manufacturing, we ensure product quality and performance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.