Book Appointment Now

About us

Company Profile

Dongguan Zhongyuan Qichuang Technology Co., Ltd and Dongguan City Jia zhan Die Cast Co., Ltdare affiliated companies which locate in Dongguan City (in Chang’an and Qiao Tou seperately). We are the comprehensive enterprises that produces hardware accessories professionally. Our business principle is “quality first and integrity first” and our service tenet is“all for customers”. Our main business: zinc/aluminum alloy die-casting. We own machines: two 800T, two 630T, one 420T, and two 280T. Zinc alloy die-casting machines: six sets, CNC machines: twenty sets.

By our professional techniques and experiences calculated for many years, we service many major customers in electron, decorative lighting, furniture and auto mobile accessory with our high-quality products and superb modes of business operation. We have a group of outstanding technical elites who are acknowledged, loved and supported by massive customers by our employees’ extra efforts.

Fast Facts

- Established:16+ years of precision die-casting experience

- Location:Chang’an Town, Dongguan—China’s mold manufacturing hub

- Core Equipment:Zinc/aluminum alloy die-casting & CNC machines. Two 800T, two 630T, one 420T, and two 280T. Zinc alloy die-casting machines: six sets, CNC machines: twenty sets.

- Precision:±0.01mm accuracy via 2.5D measurement technology

- Production Capacity:10+ million precision components annually

1.Who are we?

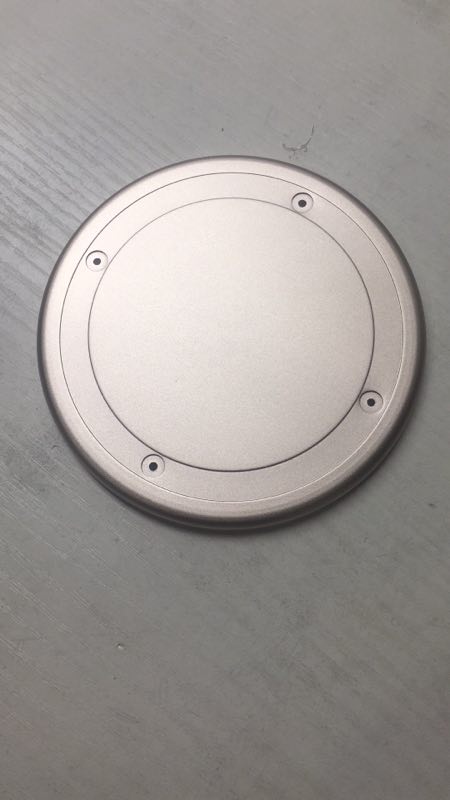

Assorted Metal Hardware

A variety of metal fittings and connectors, all expertly manufactured for industrial use.

Cable Connector Shells

Premium metal enclosures for cable connectors, ensuring durability and a sleek finish.

HDMI Port Casings

Custom - crafted metal housings for HDMI ports, precision - engineered for a perfect fit.

Logo - Style Metal Emblems

Exquisitely designed metal logo components, adding a touch of sophistication to your products.

Core Products

Precise Manufacturing, Diverse Adaptability

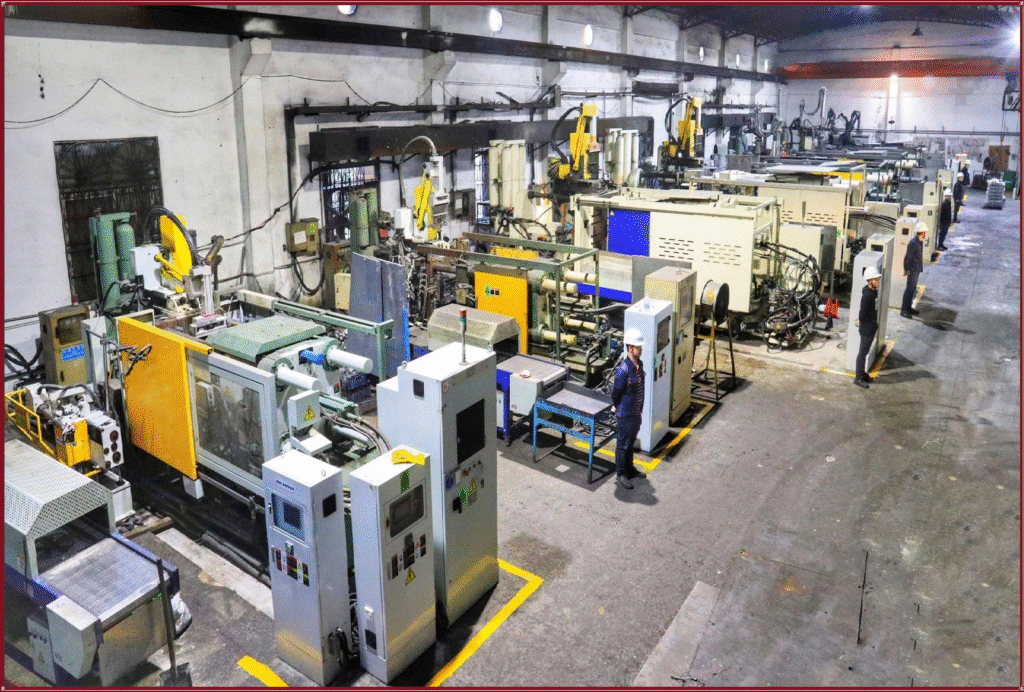

1. Precision Die-Casting Machine Series

- High-Accuracy Manufacturing: Our precision die-casting machines integrate Lijing high-pressure systems and Taiwan Weitai intelligent controls, achieving clamping forces up to 800 tons. With mold positioning accuracy of ≤±0.01mm and dimensional repeatability of ≤±0.008mm, they ensure intricate processing for complex structures like 5G connector housings and automotive sensor casings.

- High-Efficiency Production: Equipped with dual-stage pressure injection systems, these machines reach injection speeds of 5m/s, supporting integrated casting of multi-cavity molds. The automatic temperature-control modules reduce cycle times by 30%, enabling annual production of 10+ million precision components.

- Material Versatility: Compatible with ADC12 zinc alloy, A380 aluminum alloy, and magnesium alloys, they serve diverse sectors—from electronics (HDMI casings) to automotive (lightweight brackets) and medical devices (corrosion-resistant components).

2. High-Pressure Die-Casting Machine Series

- Industrial-Grade Precision: Engineered for heavy-duty applications, our high-pressure machines feature dual-platen structures to minimize flash formation, supporting 0.05mm-wall-thickness casting for aerospace-grade parts. Ideal for high-strength components in new energy vehicles and 5G base stations.

- Intelligent Process Control: The five-axis servo system enables 360° dynamic pressure adjustment, adapting to complex mold designs. Real-time data monitoring (via 2.5D measuring instruments) ensures compliance with IATF16949:2016/ ISO14001:2015/ ISO 9001:2015 standards, maintaining a 98.5% first-pass yield rate.

- Large-Scale Production: With maximum mold dimensions of 1200x800mm, these machines handle large workpieces for industrial equipment, such as LED lighting heat sinks and automotive chassis components.

3. Multi-Functional Die-Casting Cell Series

CustomizableConfigurations: Tailored to client needs, configurations include:

- Spindle power: 15-50kW for different alloy melting speeds

- Automated loading systems: Robotic arms for unmanned production lines

- Post-processing modules: Integrated polishing and deburring units

Cross-Industry Adaptability: Perfect for sectors like furniture (zinc alloy decorative parts), consumer electronics (wireless charger casings), and medical equipment (sterilizable aluminum components), with quick tooling changeovers reducing setup times by 50%.

- Die-casting systems and CNC machining system as production backbone

- Full-process QC: 2.5D measurement, X-ray flaw detection, and salt spray testing

- OEM/ODM capabilities for Huawei, ZTE, and automotive Tier 1 suppliers

- 24/7 technical support for rapid prototyping and mass production scaling

Non-metallic parts

Gold-embossed sample

Ceramic industry

Hardware parts

What do we do?

Fast facts

- Quality Assurance:Full-process QC (IQC to OQC) with 98.5% yield rate

- Key Clients:Huawei, ZTE, Pisen, Ugreen, Baseus, Luxshare

- Service Scope:OEM/ODM solutions for zinc/aluminum alloy die-castings

- Industry Reach:Electronics, telecom, automotive, lighting, medical, furniture

- Philosophy:”Trust, Team, Efficiency, Service, Innovation”

Why choose us?

Renowned for precision-engineered metal components of unwavering stability, we excel in zinc-aluminum alloy die casting, leveraging state-of-the-art Lijing and Weitai die-casting systems.

Our advanced metrology ensures micron-level accuracy, validated by rigorous end-to-end quality assurance that maintains exceptional yield rates. With expertise spanning CAD/CAM mold design to bespoke surface finishing solutions, we deliver expedited production cycles and tailored engineering for electronics, automotive, and medical sectors. As a preferred partner of global tech innovators, our commitment to technical excellence and agile support guarantees reliable, high-performance solutions that redefine industrial precision.

- Precision Manufacturing

- Temperature Resilience

- Custom Solutions

Philosophies and Values

corporate ethos is anchored in the principles of “Trust, Team, Efficiency, Service, Innovation”—guiding lights that shape our culture and define operational excellence. Trust forms the foundation of every partnership, built through unwavering integrity and transparency. Teamwork fuses diverse expertise into a cohesive force, driving collective problem-solving. Efficiency is a strategic imperative, realized through lean processes and technological innovation.

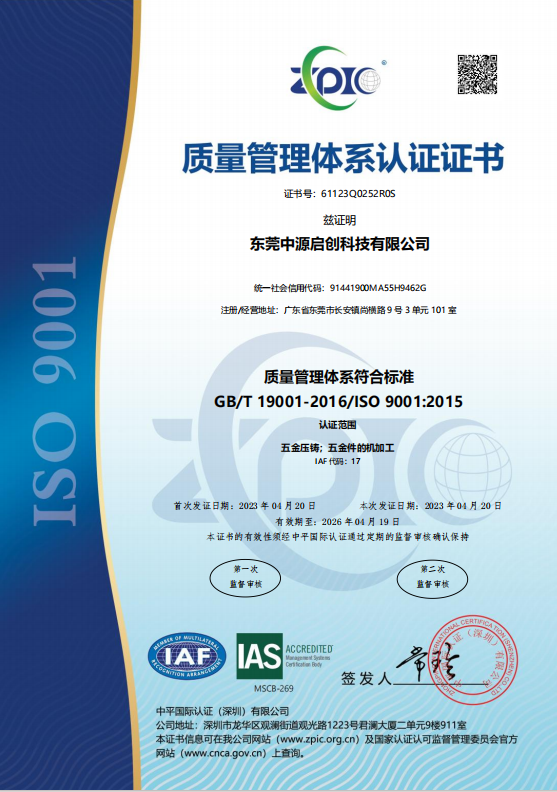

Certification Qualification

Accredited Excellence in Manufacturing Standards

Workshop Showcase

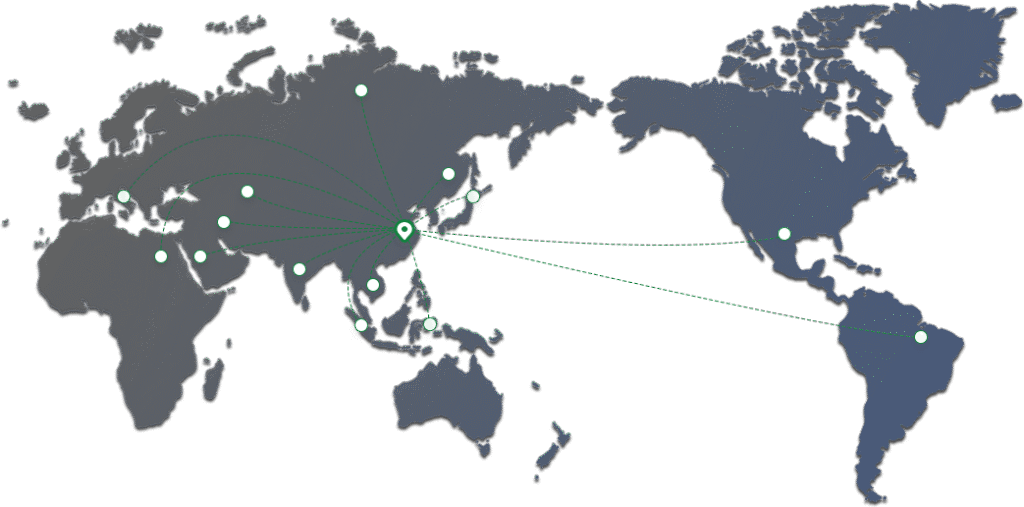

Sales network

The products are mainly exported to the United States, Japan, Australia, Europe, the Middle East and other countries and regions

It is popular in countries such as Europe, America and Southeast Asia all over the world