Book Appointment Now

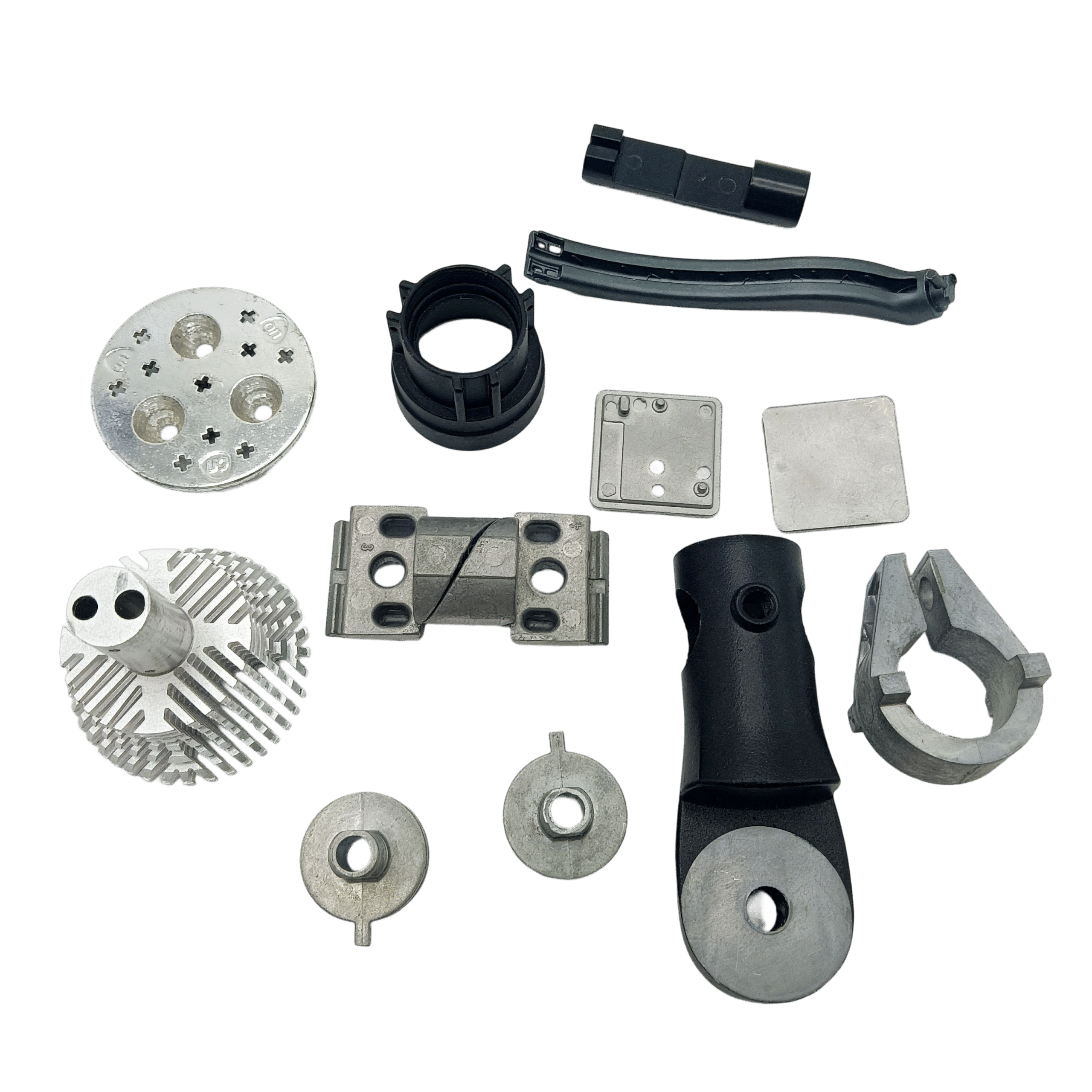

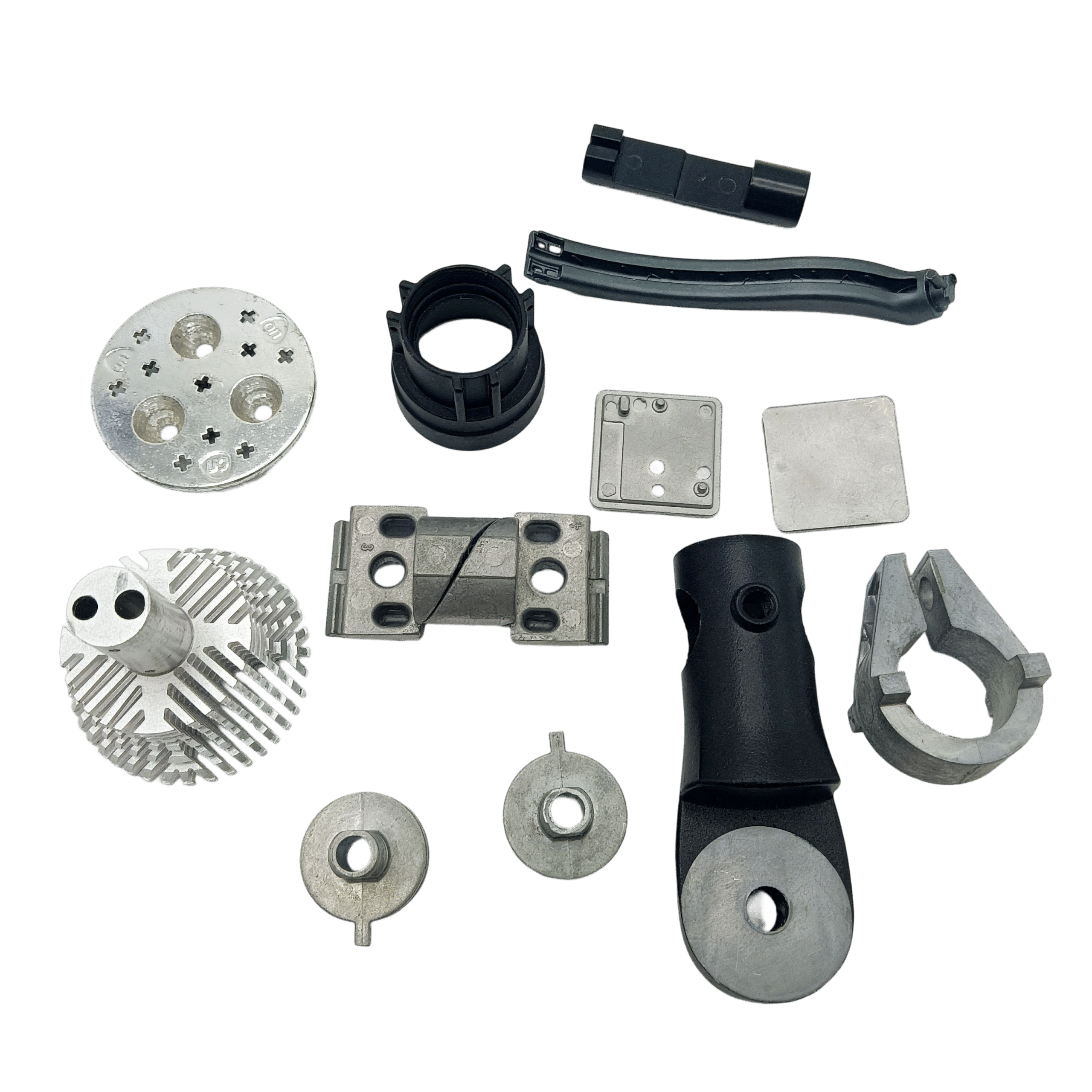

Aluminum Alloy and Zinc Alloy Die-Casting Customization and Sales Services.

Aluminum Alloy and Zinc Alloy Die-Casting Customization and Sales Services Our expertise lies in the design, customization, and sale of precision die-casting solutions for aluminum and zinc alloys. Utilizing cutting-edge die-casting technology, stringent quality controls, and a versatile service framework, we deliver comprehensive solutions tailored to diverse industries. From product concept and mold creation to large-scale production, we ensure seamless execution at every stage.

We employ advanced technologies and processes, integrating high-precision die-casting machines with clamping capabilities ranging from 100 tons to 1600 tons. This allows us to meet varied demands, from producing intricate micro-components to robust structural parts. Our team optimizes production parameters according to the specific properties of aluminum alloys like ADC12 and A380, as well as zinc alloys such as Zamak 3 and Zamak 5. This guarantees precision in molding, exceptional surface quality, and dimensional tolerances as tight as ±0.05mm. In addition, we complement our die-casting services with CNC machining centers, polishing, painting, electroplating, and other post-production processes to refine both functionality and aesthetic appeal as per customer requirements.

For personalized services, our specialized engineering team collaborates to enhance product structure designs and mold development through simulation analyses. These measures reduce production risks while accelerating developmental timelines. From initial prototypes to full-scale production runs, we implement rigorous quality-control systems utilizing advanced testing tools such as optical spectrometers and coordinate measuring devices. This ensures all materials, intermediate products, and final pieces meet stringent client specifications.

Our products are widely applied in sectors such as automotive components, electronics, smart home systems, medical equipment, hardware tools, and beyond. With a customer-focused approach, we offer flexible order options—ranging from small trial batches to consistent large-scale delivery. We also operate an integrated after-sales service system for timely technical support and feedback resolution that facilitates effective collaboration with clients.

Guided by principles of uncompromising quality, innovation in technology, and dedicated service, we aim to deliver high-value die-cast solutions that establish lasting partnerships with our customers.